Our company today

Plastic – a brilliant basis for your ideas

We, the company Werner Langer GmbH & Co. KG, manufacture custom plastic parts for a great variety of industrial sectors. With our modern production and in-house tool making facilities, we have been satisfying customers for more than 70 years – flexibly and with extensive customer services!

We are your sparring partner, from the idea to series production. We listen to you, give you tips, construct and calculate, and suggest materials and manufacturing technologies, while never losing sight of our goal to meet your requirements. Every single process, from the very first step to perfect series production, will be characterised by quality and economic efficiency.

You can count on the assistance of 120 employees who work in a three-shift system in a production area of around 10,000 m2. In our design, in-house tool making and modern plastic production departments, we develop high-quality end products designed and manufactured specifically in line with your requirements. We supply renowned national and international customers and have had nothing but positive feedback on the services we provide.

We offer our employees much room for development and a friendly work environment, which is also corroborated by our family-friendly workplace certification. Due to our size, we are an important economic factor for the City of Meschede.

History

Model signs have been produced since 1920 by our predecessor company "Kühr & Langer, Metallwarenfabrikation".

Foundation of the “Werner Langer Metallwaren” company by Werner Langer and his wife Alice. - Products: model letterings for foundries (with self-built moulding presses) and jewellery

Purchase of a plot on Bergerhütte and construction of our first own workshop

Start of the production of plastic parts

Parts of the plastics production are relocated to Eslohe-Bremke. An annexe for the production of plastic parts is built there in the course of the years

The City of Meschede turns a former agricultural area into an industrial park. We purchased a 12,500-square-metre plot

Completion of the first construction phase at “Auf dem Lohnsberg”. Stepwise implementation of another eight construction phases

The Eslohe-Bremke branch is given up and moved back to Berge

Construction of a warehouse with a separate office area. Merger of the administration, tool making and plastics production departments at the shared location of “Auf dem Lohnsberg 6”

First-time certification in accordance with DIN EN ISO 9002

Strong decline in sales due to the interior lighting industry's migration to the Far East. Expansion of our competencies into different industries, such as the sanitary, electronics, storage and materials handling sectors

Development and manufacture of the first brake rollers for pallet flow shelves

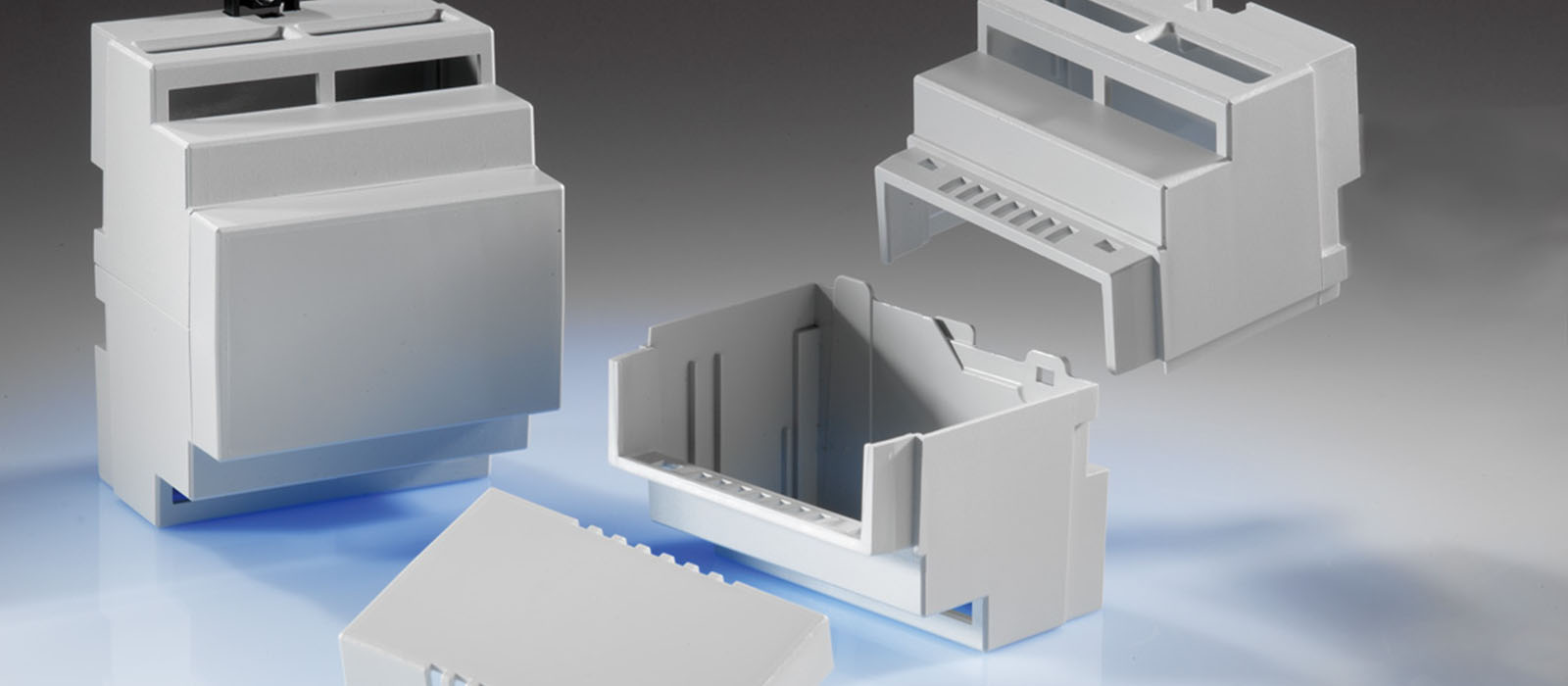

Development and fabrication of tools for manufacturing housings for modular installation devices according to DIN 43380 (top-hat rail housings)

Acquisition of a 5-axis milling machine. It is now possible to manufacture more complex and more precise tools for the production of plastics

Investment in a 5,000 KN injection moulding machine

Certification as a family-friendly company in the “Higher Sauerland District”

Changeover from copper electrodes to graphite electrodes for electrical discharge machining

Construction of a 2,500-square-metre logistics hall equipped with more than 3,000 pallet spaces at the location of “Auf dem Lohnsberg 5”

Implementation of modernisation activities and comprehensive internal restructuring measures, such as the relocation of the tool making area, the tool warehouse and the print shop

Our company celebrates its 70th anniversary